نقش ملاحظات سبک وزن در قطعات خودرو ریخته گری آلیاژ روی طراحی سبک وزن به یک جهت مهم در توسعه قطعات خودرو تبدیل شده است و قطعات ریخته گری آلیاژ...

بیشتر بخوانیدلوازم جانبی ریخته گری ماشین آلات

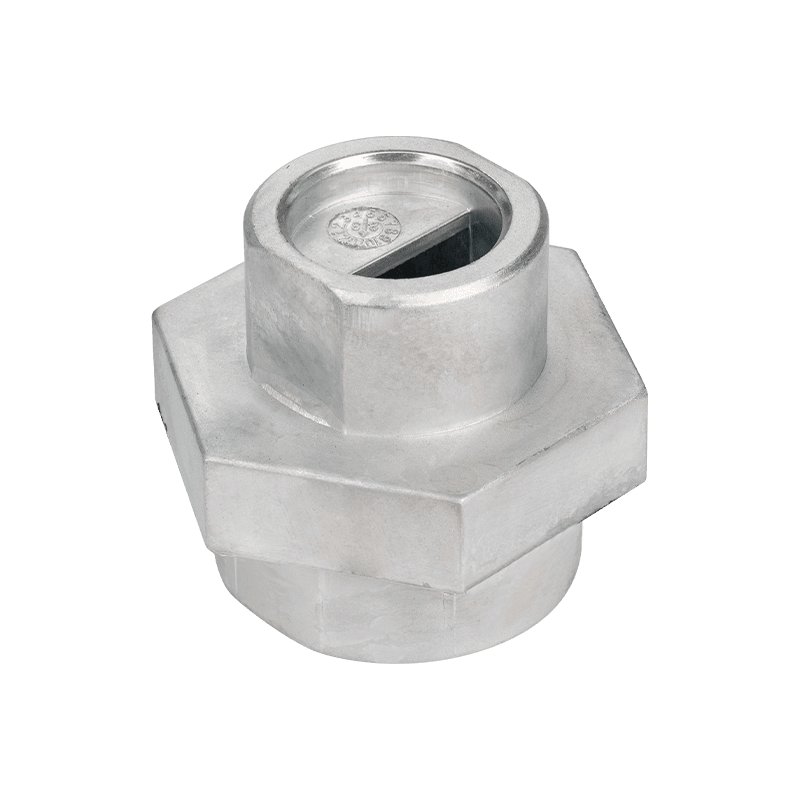

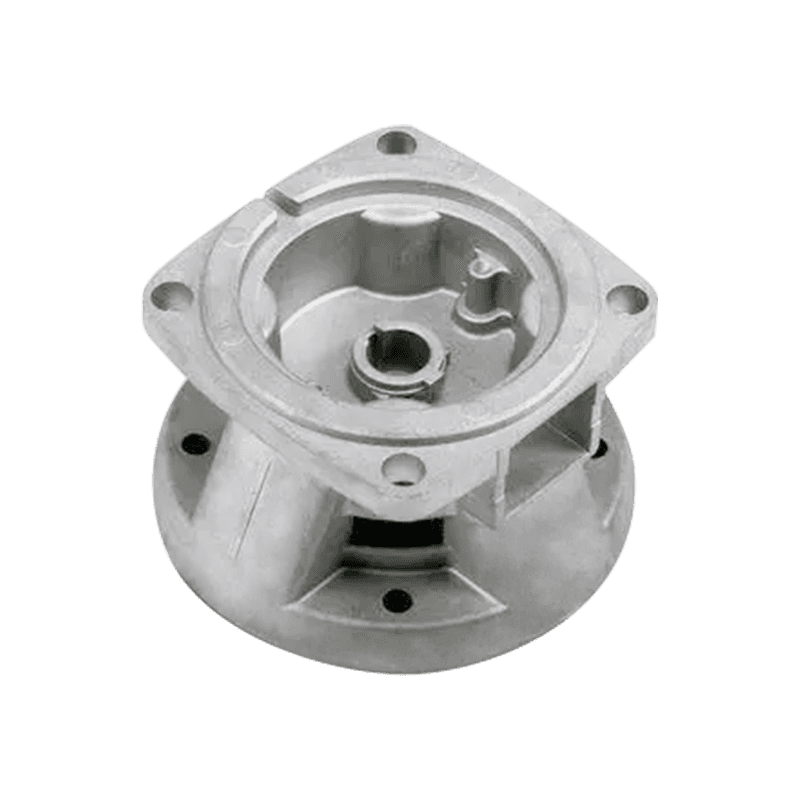

لوازم جانبی ریخته گری مکانیکی از مواد آلیاژ با کیفیت بالا برای اطمینان از دوام و استفاده طولانی مدت ساخته شده است. این لوازم جانبی برای بهبود خصوصیات مکانیکی و مقاومت در برابر سایش از ماشین آلات دقیق و تحت درمان با گرما استفاده می شوند. علاوه بر این ، آنها برای اطمینان از رعایت استانداردهای بین المللی و نیازهای مشتری در معرض کنترل کیفیت دقیق هستند.

این لوازم جانبی بر اساس فناوری و تخصص پیشرفته طراحی و تولید می شوند. آنها شامل مؤلفه هایی مانند قالب ، پایه قالب ، سر تزریق ، نازل ، سیستم های خنک کننده و سیستم های اسپری آب هستند. قالب یکی از مهمترین لوازم جانبی است که برای شکل دادن به شکل فلز مذاب استفاده می شود. از پایه قالب برای رفع قالب و پشتیبانی پایدار استفاده می شود. از سر و نازل تزریق برای کنترل جریان فلز مذاب استفاده می شود تا اطمینان حاصل شود که هر گوشه و جزئیات قالب پر شده است. از سیستم خنک کننده و سیستم اسپری آب برای کنترل میزان خنک کننده ریخته گری استفاده می شود تا از کیفیت و دقت آن اطمینان حاصل شود.

استفاده از لوازم جانبی ریخته گری مکانیکی مزایای بسیاری را به همراه دارد. اول ، آنها می توانند راندمان تولید و ظرفیت تولید را بهبود بخشند. با توجه به طراحی دقیق و تولید با کیفیت بالا این لوازم جانبی ، آنها می توانند یک فرآیند ریخته گری پایدار را فراهم کنند و از این طریق زباله ها و نقص های تولید را کاهش می دهند. ثانیا ، آنها می توانند بازیگران با کیفیت بالا را فراهم کنند. طراحی و ساخت این لوازم جانبی اطمینان حاصل می کند که فلز مذاب به طور مساوی پر و خنک می شود و در نتیجه ریخته گری های با دقت بالا و با استحکام بالا می رود. علاوه بر این ، این لوازم جانبی برای دوام و عمر طولانی طراحی شده اند و نیاز به هزینه های نگهداری و خرابی را کاهش می دهند .

| 1. نقشه ها یا نمونه ها | نقشه ها یا نمونه ها را از مشتریان دریافت می کنیم. |

| 2. تأیید نقشه ها | ما نقشه های سه بعدی را با توجه به نقاشی ها یا نمونه های 2D مشتریان ترسیم خواهیم کرد و نقشه های سه بعدی را برای تأیید برای مشتریان ارسال می کنیم. |

| 3. | ما پس از تأیید مشتریان ، یا به طور مستقیم با توجه به نقاشی های سه بعدی مشتریان نقل خواهیم کرد. |

| 4. ساخت قالب/الگوی | ما پس از دریافت سفارشات قالب از مشتریان ، قالب یا پتن درست خواهیم کرد. |

| 5. ساخت نمونه | ما با استفاده از قالب ها نمونه های واقعی خواهیم ساخت و آنها را برای تأیید به مشتریان ارسال می کنیم. |

| 6. تولید انبوه | ما پس از دریافت تأیید و سفارشات مشتریان ، محصولات را تولید خواهیم کرد. |

| 7. بازرسی | ما محصولات را توسط بازرسان خود بازرسی خواهیم کرد یا از مشتریان می خواهیم که پس از اتمام ، با ما بازرسی کنند. |

| 8 | ما پس از دریافت نتیجه بازرسی و تأیید مشتریان ، کالاها را به مشتریان ارسال خواهیم کرد. |

| فرآیند: | 1) اکستروژن ریخته گری / پروفایل |

| 2) ماشینکاری: چرخش CNC ، فرز ، حفاری ، سنگ زنی ، استفاده مجدد و نخ | |

| 3) درمان سطح | |

| 4) بازرسی و بسته بندی | |

| مواد موجود: | 1) آلیاژهای آلومینیوم ریخته گری: ADDC10 ، ADC12 ، A360 ، A380 ، ZL110 ، ZL101 و غیره. |

| 2) اکستروژن پروفایل آلیاژهای آلومینیوم: 6061 ، 6063 | |

| 3) آلیاژهای زین ریخته گری: ZDC1 ، ZD2 ، Zamak 3 ، Zamak 5 ، Za8 ، ZL4-1 و غیره. | |

| تصفیه سطح: | صیقل |

| انفجار شات | |

| ماسهبازی | |

| روکش پودری | |

| بوی | |

| آبکاری | |

| انفعال | |

| پوشش الکترونیکی | |

| پوشش T | |

| و غیره | |

| تحمل: | /-0.01mm |

| وزن در هر واحد: | 0.01-5 کیلوگرم |

| سفارش زمان سرب: | 20-45 روز (با توجه به کمیت و پیچیدگی محصول 1 |

-

-

دقت ابعادی در ریخته گری سرب ریخته گری سرب به دلیل توانایی آن در دستیابی به دقت ابعادی بالا شناخته شده است، که در صنایعی که نیاز به هندسه و تناسب قطعات ثاب...

بیشتر بخوانید -

نمای کلی براکت های پروفیل آلومینیومی براکت های پروفیل آلومینیومی به دلیل سبک بودن، مقاومت در برابر خوردگی و سهولت نصب، اجزای پرکاربردی در کاربردهای مختلف ...

بیشتر بخوانید

Why choose our Machinery Die Casting Accessories?

Our machinery die casting accessories are made of high-strength alloy materials, which have superior mechanical properties and durability. In the production process, we use strictly screened high-quality materials to ensure the purity and performance of the raw materials of each accessory. For example, in a high temperature and high pressure working environment, our accessories can maintain their stable mechanical properties, and will not affect their service life and reliability due to the harsh environment. Whether it is automotive, aerospace, or other industrial applications, our machinery die casting accessories can meet the most demanding use requirements.

In addition to the superiority of materials, every link in our production process is strictly carried out in accordance with international standards. We have a complete quality management system to ensure that every machinery die casting accessory undergoes strict quality inspection before leaving the factory. These inspections cover multiple aspects from dimensional accuracy, mechanical strength to surface finish, ensuring that every detail of each accessory meets the design specifications. Our testing equipment and technicians have rich experience and expertise, and can promptly detect and correct any problems that may occur in the production process, thereby ensuring the high quality of the product.

Technological innovation and process improvement are our constant pursuit. We cooperate with many scientific research institutions and universities to focus on technology research and development and process optimization. By introducing advanced die-casting technology and equipment, we have not only improved production efficiency, but also greatly improved the precision and consistency of products. For example, we have introduced high-pressure and high-speed die-casting machines, which can complete the filling and cooling of molten metal in a short time, thereby ensuring the high density and high strength of the product. In addition, we have also adopted computer simulation technology to optimize die-casting parameters, reduce defects and improve product quality by simulating the flow and solidification behavior during the die-casting process.

Customer service is the top priority of our work. We have a professional after-sales service team that can respond to customer needs and feedback in a timely manner. Whether it is product consultation, usage guidance or after-sales service, we strive to be timely, professional and thoughtful. Our customer service team is regularly trained to ensure that they can provide the best service experience. We believe that through our efforts, every customer can enjoy an unparalleled service experience.

What is unique about our die-casting process?

Our die-casting process uses the most advanced die-casting equipment and technology. We have introduced high-pressure and high-speed die-casting machines, which can complete the filling and cooling of molten metal in a short time, thereby producing high-quality mechanical die-casting parts. The high-pressure and high-speed die-casting process can not only improve the density and strength of the product, but also reduce casting defects such as pores and shrinkage holes, and improve the consistency and reliability of the product. Our die-casting equipment is provided by world-class manufacturers, with high automation and precision control functions, which can be precisely controlled and operated to ensure that every accessory meets the design requirements.

We strictly control every link in the die-casting process. The die-casting process includes multiple steps such as smelting, casting, cooling, and cleaning, and each step requires a high degree of professional skills and experience. Our die-casting workers have undergone rigorous training and have rich practical experience, and can achieve excellence in every link. In particular, we have carried out fine regulation on key parameters such as temperature control, casting speed and cooling time to ensure the quality and consistency of the product. The temperature control system we use can monitor and adjust the temperature of the molten metal in real time to ensure the stability and consistency of the temperature. In addition, we have adopted an advanced cooling system to further improve the quality of the product by controlling the cooling rate and reducing thermal stress and deformation.

We also pay great attention to the selection and processing of materials. High-quality mechanical die-casting accessories require high-quality raw materials. We have established long-term cooperative relationships with many high-quality material suppliers to ensure that each batch of materials can meet our high standards. Before entering the production line, the materials are also strictly tested and processed to remove impurities and defects and improve the purity and performance of the materials. The materials we use not only have excellent mechanical properties, but also have good corrosion resistance and wear resistance, and can maintain stable performance in harsh working environments.

Many innovative elements are also incorporated into our die-casting process. We have introduced advanced computer simulation technology to optimize die-casting parameters, reduce defects and improve product quality by simulating the flow and solidification behavior during the die-casting process. The application of these innovative technologies gives our mechanical die-casting accessories a clear competitive advantage in the market. For example, we optimized the design of the casting system through simulation technology, reduced the turbulence and inclusions of the molten metal, and improved the internal quality and surface quality of the product. We have also developed special die-casting molds, which have good thermal conductivity and wear resistance, can maintain stable performance in high temperature and high pressure working environments, and extend the service life of the mold.

How to improve the performance of mechanical equipment by using our Machinery Die Casting Accessories?

The performance of mechanical equipment depends largely on the quality of the accessories used. High-quality mechanical die-casting accessories can not only improve the working efficiency of the equipment, but also extend the service life of the equipment and reduce maintenance costs. Our mechanical die-cast parts are well designed and perform well, significantly improving the overall performance of mechanical equipment.

Our mechanical die-cast parts offer excellent mechanical strength and wear resistance. Accessories made of high-strength alloy materials have excellent tensile strength and impact resistance, and can maintain long-term stable performance under high load and high wear conditions. This is critical to increasing the reliability and service life of your equipment. Our accessories undergo a special heat treatment process to further improve the hardness and wear resistance of the material and extend the service life of the accessories. Whether in high-temperature, high-pressure or high-wear working environments, our accessories perform well to ensure long-term stable operation of the equipment.

Our mechanical die-cast parts are precision machined and rigorously inspected with high precision and consistency. Whether it is dimensional tolerances or surface finish, our accessories meet the most demanding requirements. High-precision accessories can not only improve the assembly quality of the equipment, but also reduce vibration and noise during equipment operation, thereby improving the smooth operation and comfort of the equipment. For example, the surface of our accessories is finely ground and polished, with excellent surface quality and smoothness, which can reduce friction and wear and improve the operating efficiency and service life of the equipment.

Our accessories also offer excellent corrosion resistance. Mechanical equipment often comes into contact with various corrosive media during operation, such as water, oil, chemicals, etc. Our mechanical die-cast parts undergo special anti-corrosion treatment, which can effectively resist various corrosion factors and extend the service life of the parts. The anti-corrosion coating we use has excellent corrosion resistance and can maintain stable performance in harsh environments, ensuring long-term stable operation of the equipment. Our accessories have also undergone rigorous salt spray tests and corrosion tests to ensure their excellent performance in various complex environments.

You can also enjoy greater work efficiency with our mechanical die-cast accessories. Our accessories are well designed and easy to install, which can greatly shorten the assembly time and maintenance time of the equipment and improve production efficiency. For example, our accessories are modular in design, allowing for quick replacement and installation, reducing equipment downtime. The high reliability and long service life of accessories can also reduce equipment failure rates and downtime, thereby improving equipment utilization and production efficiency.

آیا به محصولات ما علاقه دارید

نام و آدرس ایمیل خود را بگذارید تا سریعاً قیمت ها و جزئیات ما را بدست آورید.